Description

Full-Size Bumper Strip

Product Overview

The full-size bumper strip, also known as a conveyor paddle, is an essential component in material handling systems. It is designed to push, scrape, or guide bulk materials—including granules, powders, and irregular solids—along conveyor belts or troughs, ensuring efficient and stable material transportation with minimal leakage or accumulation.

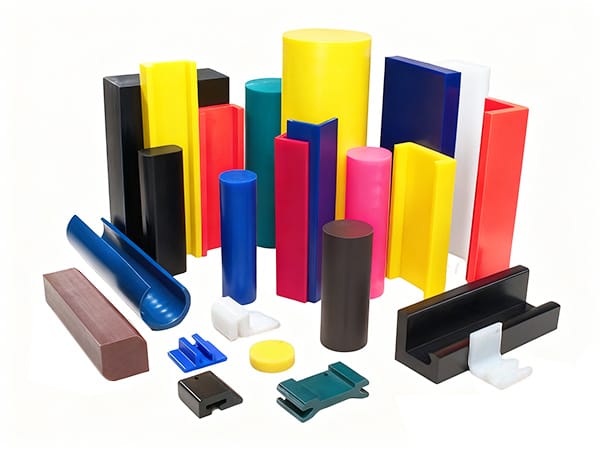

Key Materials

Crafted from high-performance materials such as UHMWPE, HDPE, PP, and reinforced rubber, the conveyor paddle delivers superior durability and reliability. These materials provide excellent wear resistance, impact resistance, and chemical corrosion resistance, allowing the paddle to perform effectively in harsh industrial environments.

Features & Advantages

High Wear Resistance: Long-lasting performance even under continuous friction and heavy use

Impact and Chemical Resistance: Withstands collisions, abrasion, and exposure to corrosive substances

Temperature Resistant: Performs reliably across varying operational temperatures

Customizable Design: Size, shape, and installation method can be tailored for different conveyor systems

Improved Efficiency: Optimized design reduces material spillage and accumulation, enhancing conveyor performance

Versatile Application: Compatible with screw conveyors, belt conveyors, and other material transport systems

Applications

The full-size bumper strip is widely used in industries including:

Mining and mineral processing

Agriculture and grain handling

Food processing

Plastic and chemical production

Bulk material transport systems

Benefits

Installing high-quality UHMWPE or HDPE conveyor paddles significantly extends the service life of conveyor systems, reduces maintenance costs, and improves operational efficiency. Custom options ensure a perfect fit for a wide range of industrial applications.