Table of Contents

Introduction

Ultra High Molecular Weight Polyethylene (UHMWPE) is a high-performance engineering plastic that has become essential in many demanding industrial environments. Its exceptional wear resistance, low friction behavior, and outstanding impact strength make it a preferred material for applications where conventional plastics or metals experience rapid failure.

With the increasing demand for durable, lightweight, and maintenance-free materials, UHMWPE sheets and custom-machined UHMWPE components are widely used across material handling, mining, marine, food processing, and heavy industrial equipment sectors.

This article provides a comprehensive explanation of UHMWPE material, focusing on its structure, properties, performance advantages, processing methods, and industrial applications, helping engineers and buyers make informed material decisions.

Overview of UHMWPE Material

UHMWPE is a thermoplastic polymer belonging to the polyethylene family, characterized by an extremely high molecular weight typically ranging from three to nine million g/mol. This molecular weight is several times higher than that of standard HDPE, resulting in significantly enhanced mechanical performance.

The long polymer chains form a dense and highly entangled structure, giving UHMWPE exceptional toughness and durability. UHMWPE is commonly produced in sheet, rod, tube, and profile forms and can be further machined into custom components.

Molecular Structure and Load Distribution

The molecular structure of UHMWPE plays a critical role in its mechanical behavior. The ultra-long molecular chains distribute applied stress evenly throughout the material, reducing localized stress concentrations.

This unique structure allows UHMWPE to resist crack initiation and propagation, even under repeated impact and continuous sliding conditions. As a result, UHMWPE components maintain their integrity and performance over long service periods.

Wear Resistance in Industrial Conditions

Wear resistance is one of the most important performance characteristics of UHMWPE. In abrasive environments involving bulk materials, powders, minerals, or repeated sliding contact, UHMWPE demonstrates superior resistance compared to many traditional materials.

UHMWPE liners and wear components help prevent material buildup, reduce friction-related damage, and significantly extend equipment service life. This leads to lower maintenance frequency and reduced operational costs.

Low Friction Characteristics and Operational Efficiency

UHMWPE has a naturally low coefficient of friction, allowing smooth movement between contacting surfaces without external lubrication. This self-lubricating behavior is particularly valuable in systems where oil or grease contamination must be avoided.

Reduced friction improves energy efficiency, minimizes wear on mating components, and lowers operational noise levels in automated and continuous-running equipment.

Impact Strength and Temperature Performance

UHMWPE maintains excellent impact resistance across a wide temperature range. Unlike many engineering plastics that become brittle in cold environments, UHMWPE retains toughness and flexibility at low temperatures.

This property makes UHMWPE suitable for outdoor installations, cold storage facilities, ports, and mining operations exposed to seasonal or extreme temperature variations.

Chemical Resistance and Moisture Stability

UHMWPE exhibits strong resistance to acids, alkalis, salts, and many industrial chemicals. It does not corrode and absorbs virtually no moisture, ensuring dimensional stability in wet or humid environments.

These characteristics make UHMWPE particularly suitable for marine applications, food processing equipment, and washdown areas where consistent performance is required.

Machinability and Custom Processing Options

UHMWPE can be machined using standard CNC processes, including milling, turning, drilling, and cutting. Sheets and rods can be fabricated into complex geometries according to technical drawings or samples.

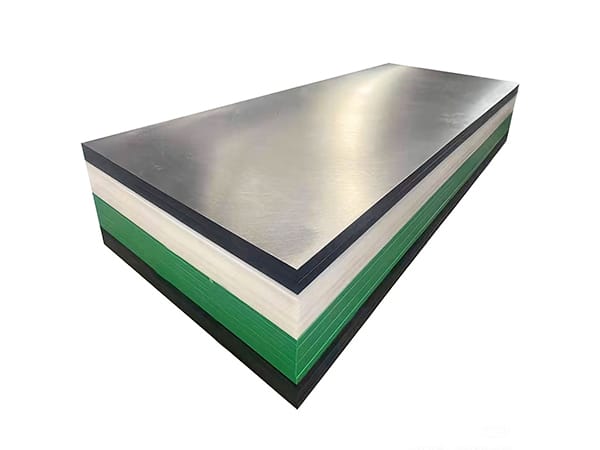

Custom processing allows manufacturers to supply UHMWPE components with specific dimensions, tolerances, surface finishes, and colors, ensuring optimal integration into industrial systems.

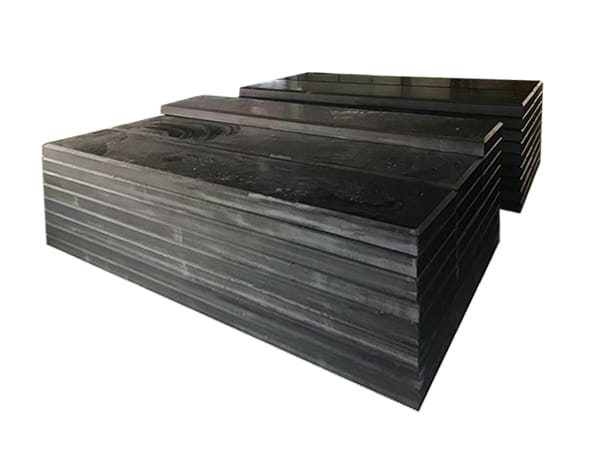

UHMW PE Sheet

- Thickness: 3-200mm

- Max Width: 5260mm

- Length: Customizable production

Typical Industrial Applications of UHMWPE

UHMWPE is widely used across various industries due to its balanced performance profile.

In conveyor systems, UHMWPE is commonly used for wear strips, guide rails, chain guides, and sliding plates.

In mining and bulk material handling, it serves as chute liners, hopper liners, and impact panels to improve material flow.

In marine and port facilities, UHMWPE is applied in fender pads, dock protection systems, and sliding bearings.

In food processing environments, food-grade UHMWPE is used for cutting boards, conveyor components, and guiding parts.

In heavy machinery and industrial equipment, UHMWPE is machined into wear pads, sliding blocks, and protective liners.

Comparison Between UHMWPE and Other Engineering Plastics

The table below highlights the key performance differences between UHMWPE and other commonly used engineering plastics.

| Property | UHMWPE | HDPE | Nylon |

|---|---|---|---|

| Wear Resistance | Excellent | Good | Moderate |

| Coefficient of Friction | Very Low | Low | Moderate |

| Impact Strength | Excellent | Good | Moderate |

| Water Absorption | Very Low | Very Low | High |

| Chemical Resistance | Excellent | Excellent | Moderate |

| Machinability | Good | Good | Good |

This comparison shows why UHMWPE is often selected for wear-intensive and sliding applications where long service life is critical.

Key Considerations for Material Selection

When selecting UHMWPE for industrial use, factors such as load conditions, sliding speed, environmental exposure, and temperature range should be carefully evaluated.

Material grade, thickness, and machining method can significantly affect performance. Partnering with an experienced UHMWPE manufacturer helps ensure the correct material and processing approach for each application.

Conclusion

UHMWPE is a versatile engineering plastic offering exceptional wear resistance, low friction, impact strength, and chemical stability. Its performance advantages make it an ideal material for demanding industrial environments where reliability and durability are essential.

By choosing UHMWPE sheets or custom-machined UHMWPE components, equipment manufacturers and operators can reduce maintenance costs, improve operational efficiency, and extend equipment service life.

FAQ

What makes UHMWPE different from standard polyethylene materials?

UHMWPE has an extremely high molecular weight, giving it superior wear resistance, impact strength, and sliding performance compared to standard polyethylene materials.

Is UHMWPE suitable for continuous sliding applications?

Yes, UHMWPE is widely used in continuous sliding and wear applications due to its low friction and excellent abrasion resistance.

Can UHMWPE be used in wet or humid environments?

UHMWPE absorbs almost no moisture and maintains stable performance in wet and humid conditions, making it suitable for marine and washdown applications.

Is UHMWPE safe for food processing equipment?

Food-grade UHMWPE is available and commonly used in food processing and packaging equipment where hygiene and wear resistance are required.

What should be considered when ordering custom UHMWPE parts?

Key considerations include operating conditions, load requirements, temperature range, chemical exposure, and machining tolerances to ensure optimal performance.