Table of Contents

Introduction

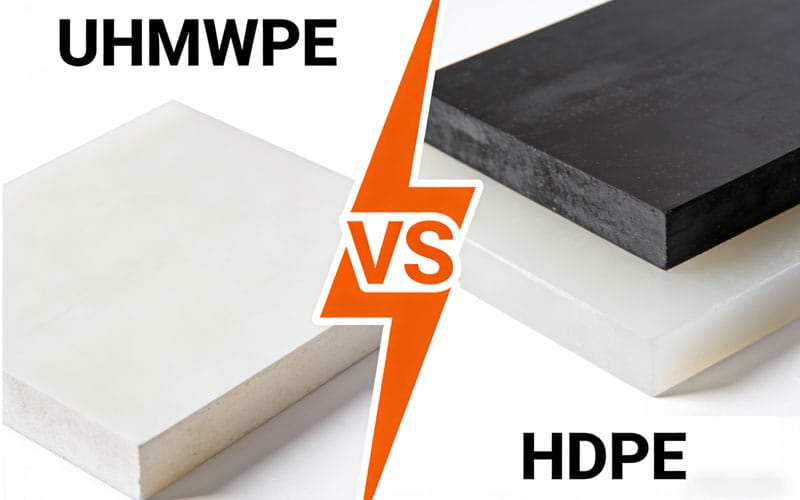

When comparing engineering plastics for industrial applications, UHMWPE vs HDPE is one of the most common material selection questions faced by engineers and procurement professionals. Although both materials belong to the polyethylene family, their performance characteristics and service life differ significantly.

Understanding the differences between UHMWPE vs HDPE is essential for selecting the right plastic material, controlling maintenance costs, and improving equipment reliability. This article provides a detailed analysis of UHMWPE vs HDPE, focusing on structure, wear performance, friction behavior, durability, and real industrial applications.

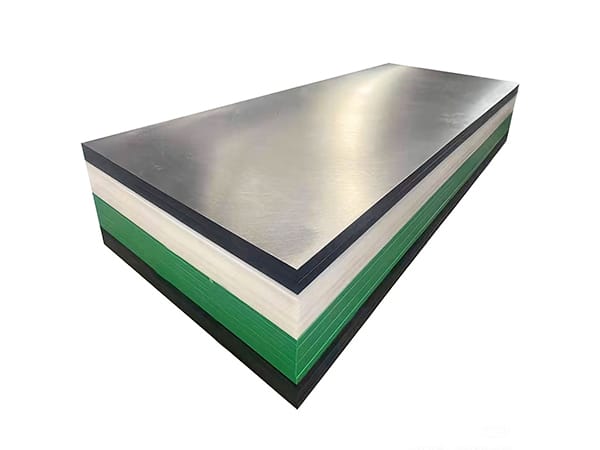

General Characteristics of UHMWPE and HDPE

In the comparison of UHMWPE vs HDPE, UHMWPE is known for its extremely high molecular weight, which gives it superior wear resistance and impact strength. It is designed for demanding environments involving abrasion, sliding, and repeated impact.

HDPE, in contrast, has a lower molecular weight but higher density. In UHMWPE vs HDPE applications, HDPE is often chosen for general-purpose uses where cost efficiency and chemical resistance are important, but extreme wear resistance is not required.

Molecular Structure and Polymer Chain Behavior

The most fundamental difference in UHMWPE vs HDPE lies in molecular structure. UHMWPE has ultra-long polymer chains that form a highly entangled structure, allowing stress to be distributed more evenly.

In UHMWPE vs HDPE comparisons, HDPE’s shorter molecular chains provide higher rigidity but lower resistance to long-term abrasion. This structural difference explains why UHMWPE performs better in high-wear applications.

Wear Resistance and Long-Term Surface Performance

Wear resistance is one of the key decision factors in UHMWPE vs HDPE material selection. UHMWPE offers outstanding abrasion resistance, even under continuous sliding and contact with bulk materials.

In UHMWPE vs HDPE scenarios involving conveyors or chutes, HDPE generally wears faster, leading to more frequent replacement and maintenance.

Impact Strength and Resistance to Mechanical Shock

Another important consideration in UHMWPE vs HDPE is impact strength. UHMWPE maintains excellent toughness under repeated mechanical shock and low temperatures.

While HDPE provides good impact resistance, UHMWPE vs HDPE testing shows that UHMWPE performs better in heavy-duty and impact-intensive environments.

Friction Properties and Sliding Efficiency

UHMWPE has a very low coefficient of friction and natural self-lubricating properties. This allows smooth sliding motion without external lubrication, reducing wear on both the UHMWPE component and mating surfaces.

HDPE has a higher coefficient of friction compared to UHMWPE. While still suitable for many applications, HDPE may require lubrication or experience increased wear in sliding systems.

Lower friction also contributes to reduced energy consumption and quieter operation, making UHMWPE advantageous in automated and continuous-running equipment.

Noise Reduction and Operational Comfort

Noise reduction is an often-overlooked factor in material selection. UHMWPE significantly reduces noise generated by sliding, impact, and material flow.

HDPE offers some noise reduction compared to metal components but does not perform as well as UHMWPE in high-speed or high-impact environments. For facilities with strict noise control requirements, UHMWPE is frequently selected.

Chemical Resistance and Environmental Adaptability

Both UHMWPE and HDPE provide excellent resistance to a wide range of chemicals, including acids, alkalis, and industrial cleaning agents. They are corrosion-resistant and unaffected by moisture.

UHMWPE offers slightly better long-term performance in harsh environments where chemical exposure is combined with continuous wear. HDPE remains a cost-effective option for applications with less severe operating conditions.

Temperature Performance and Environmental Conditions

UHMWPE maintains its mechanical properties across a wide temperature range and retains impact resistance in low-temperature environments. This makes it suitable for outdoor equipment and cold storage facilities.

HDPE performs well at normal operating temperatures but may become less impact-resistant in very cold conditions. Temperature exposure should be considered during material selection.

Machining Behavior and Manufacturing Considerations

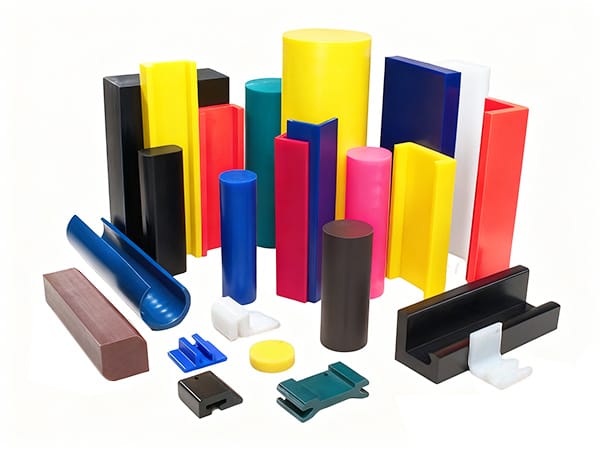

Both UHMWPE and HDPE can be machined using CNC milling, turning, drilling, and cutting processes. UHMWPE requires more careful machining due to its toughness and flexibility but allows the production of durable wear components.

HDPE is easier to machine and thermoform, which can reduce manufacturing time and cost for high-volume or less complex parts. Fabrication requirements should be evaluated alongside performance needs.

Typical Applications Where UHMWPE Is Preferred

UHMWPE is commonly selected for applications where wear resistance, sliding performance, and durability are critical.

Typical applications include conveyor wear strips, guide rails, chain guides, chute liners, hopper liners, marine fender pads, sliding bearings, and wear pads for heavy machinery.

Typical Applications Where HDPE Is Preferred

HDPE is widely used in applications where cost efficiency, chemical resistance, and structural stability are the primary concerns.

Common uses include water tanks, storage containers, piping systems, cutting boards, protective panels, and liners in low-wear environments.

Performance Comparison Between UHMWPE and HDPE

The table below summarizes the key performance differences between UHMWPE and HDPE.

| Property | UHMWPE | HDPE |

|---|---|---|

| Molecular Weight | Extremely High | Moderate |

| Wear Resistance | Excellent | Good |

| Coefficient of Friction | Very Low | Low |

| Impact Strength | Excellent | Good |

| Noise Reduction | Excellent | Moderate |

| Water Absorption | Very Low | Very Low |

| Chemical Resistance | Excellent | Excellent |

| Machinability | Good | Excellent |

| Typical Service Life | Long | Moderate |

| Cost Level | Higher | Lower |

This comparison illustrates why UHMWPE is preferred for performance-critical applications, while HDPE remains popular for cost-sensitive projects.

Total Cost of Ownership Considerations

Although UHMWPE typically has a higher initial material cost than HDPE, its longer service life often results in lower total cost of ownership.

Reduced downtime, fewer replacements, lower maintenance requirements, and improved operational efficiency can offset the higher upfront cost of UHMWPE in many industrial applications.

How to Select the Right Material for Your Application

Selecting the right material in UHMWPE vs HDPE depends on operating conditions. For high-wear, sliding, or impact-intensive applications, UHMWPE is generally recommended.

For low-wear and budget-sensitive projects, UHMWPE vs HDPE evaluation may lead to choosing HDPE.

Conclusion

UHMWPE and HDPE are both valuable engineering plastics with distinct advantages. UHMWPE excels in wear resistance, impact strength, low friction, and noise reduction, making it ideal for demanding industrial applications. HDPE offers good strength, chemical resistance, and cost efficiency for general-purpose use.

Understanding the differences between UHMWPE and HDPE enables engineers and procurement professionals to make informed material choices that improve equipment reliability and reduce long-term costs.

FAQ

What is the most important factor when choosing between UHMWPE and HDPE?

The most important factor is the level of wear and friction in the application. UHMWPE is preferred for high-wear environments, while HDPE suits lower-wear conditions.

Does UHMWPE last longer than HDPE?

Yes, in wear-intensive applications UHMWPE typically provides a significantly longer service life than HDPE.

Can UHMWPE and HDPE both be used in food processing?

Both materials are available in food-grade versions and are commonly used in food processing equipment.

Is UHMWPE more expensive than HDPE?

UHMWPE usually has a higher initial cost, but its longer service life can reduce total operating costs.

How do I ensure correct material selection for my project?

Evaluate operating conditions and consult with an experienced plastic manufacturer to select the most suitable material.