In the ever-evolving industrial landscape, the choice of materials plays a crucial role in determining the efficiency, durability, and safety of various applications. Engineering plastics have emerged as a preferred choice for many industries due to their exceptional properties and versatility. Shandong Yunzhan Plastic Industry Co., Ltd. is at the forefront of providing high-quality engineering plastic products that meet the diverse needs of modern industrial applications.

Table of Contents

What are Engineering Plastics?

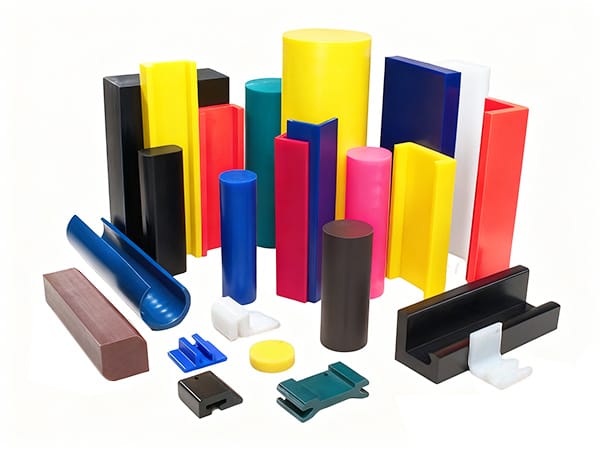

Engineering plastics are a group of plastic materials that have superior mechanical and thermal properties compared to commodity plastics. They are designed to withstand harsh environmental conditions, heavy loads, and chemical exposure, making them ideal for use in a wide range of industrial applications. Some of the most commonly used engineering plastics include UHMWPE, HDPE, Nylon, PP, and PVC.

Key Properties of Engineering Plastics:

- High Strength: Engineering plastics offer exceptional strength and stiffness, allowing them to replace traditional materials such as metal and wood in many applications.

- Chemical Resistance: They are highly resistant to a wide range of chemicals, making them suitable for use in chemical processing, food and beverage, and pharmaceutical industries.

- Thermal Stability: Engineering plastics can withstand high temperatures without losing their mechanical properties, making them ideal for use in high-temperature environments.

- Low Friction: Many engineering plastics have a low coefficient of friction, reducing wear and tear on moving parts and improving the efficiency of machinery.

- Lightweight: Despite their exceptional strength, engineering plastics are lightweight, reducing the overall weight of equipment and vehicles, and improving fuel efficiency.

Benefits of Using Engineering Plastics in Industrial Applications

1. Cost-Effective Solution

Engineering plastics offer a cost-effective alternative to traditional materials such as metal and wood. They are often less expensive to produce and process, and their lightweight nature reduces transportation and installation costs. Additionally, their long lifespan and low maintenance requirements further contribute to cost savings over the long term.

2. Improved Safety

The use of engineering plastics in industrial applications can significantly improve safety. Their high strength and impact resistance can help prevent accidents and injuries, while their chemical resistance can protect workers from exposure to harmful chemicals. Additionally, their non-conductive properties make them ideal for use in electrical applications, reducing the risk of electrical shock.

3. Enhanced Performance

Engineering plastics can enhance the performance of industrial equipment and machinery. Their low friction properties can reduce energy consumption and improve the efficiency of moving parts, while their thermal stability can help prevent overheating and extend the lifespan of equipment. Additionally, their customizable nature allows for the design of parts that are tailored to specific applications, improving overall performance.

4. Environmental Sustainability

Many engineering plastics are recyclable, making them an environmentally sustainable choice. Their lightweight nature can also reduce fuel consumption and greenhouse gas emissions during transportation. Additionally, their long lifespan and low maintenance requirements can reduce the amount of waste generated by industrial applications.

Applications of Engineering Plastics in Various Industries

1. Automotive Industry

Engineering plastics are widely used in the automotive industry due to their lightweight nature and high strength. They are used in the production of various components such as bumpers, interior trim, and engine parts, reducing the overall weight of vehicles and improving fuel efficiency.

2. Aerospace Industry

The aerospace industry requires materials that are lightweight, strong, and resistant to extreme temperatures. Engineering plastics are used in the production of various aerospace components such as aircraft interiors, engine parts, and structural components, improving the performance and safety of aircraft.

3. Medical Industry

Engineering plastics are used in the medical industry due to their biocompatibility and chemical resistance. They are used in the production of various medical devices such as surgical instruments, implants, and drug delivery systems, improving the safety and effectiveness of medical treatments.

4. Construction Industry

Engineering plastics are used in the construction industry due to their durability and weather resistance. They are used in the production of various construction materials such as pipes, fittings, and insulation, improving the durability and energy efficiency of buildings.

Conclusion

Engineering plastics offer a wide range of benefits for industrial applications, including cost savings, improved safety, enhanced performance, and environmental sustainability. Shandong Yunzhan Plastic Industry Co., Ltd. is a leading provider of high-quality engineering plastic products that meet the diverse needs of modern industrial applications. Whether you are looking for standard products or customized solutions, we have the expertise and resources to help you find the right engineering plastic for your application.

FAQ

What are the differences between engineering plastics and commodity plastics?

Engineering plastics have superior mechanical and thermal properties compared to commodity plastics. They are designed to withstand harsh environmental conditions, heavy loads, and chemical exposure, making them ideal for use in industrial applications. Commodity plastics, on the other hand, are less expensive and have lower performance properties, making them suitable for use in consumer goods and packaging.

Can engineering plastics be recycled?

Yes, many engineering plastics are recyclable. However, the recycling process can be more complex than that of commodity plastics due to their higher performance properties. It is important to consult with a professional recycling company to ensure that engineering plastics are recycled properly.

What factors should I consider when choosing engineering plastics for my application?

When choosing engineering plastics for your application, you should consider factors such as mechanical properties, chemical resistance, thermal stability, and cost. It is also important to consult with a professional engineer or material scientist to ensure that you choose the right material for your specific application.

Can engineering plastics be customized to meet my specific requirements?

Yes, engineering plastics can be customized to meet your specific requirements. Shandong Yunzhan Plastic Industry Co., Ltd. offers customized plastic parts manufacturing services, allowing you to create parts that are tailored to your exact specifications.