Description

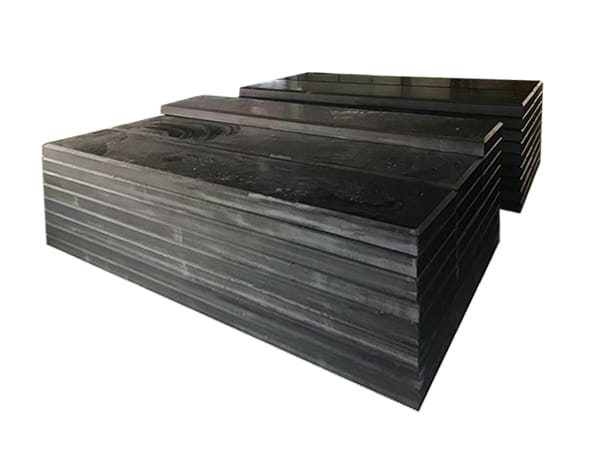

UHMW (Ultra High Molecular Weight Polyethylene) is a common machinable plastic known for durability, versatility and cost-effectiveness as well as abrasion, impact and chemical resistances. UHMW plastic features a molecular weight that ranges from 3.1 million to 100 million grams per mole, with an abrasion resistance that continues to improve as molecular weight increases.

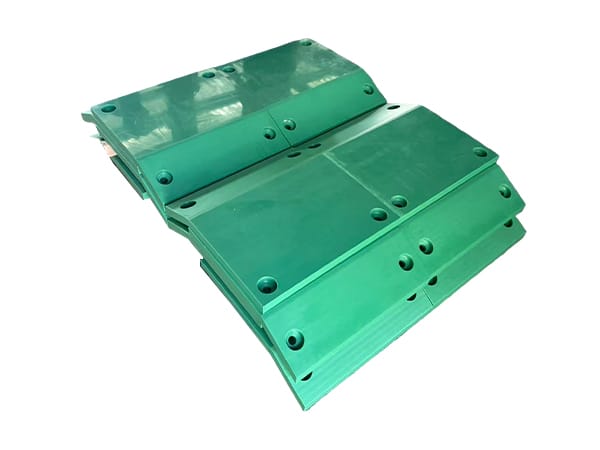

Reprocessed UHMW is an eco-friendly and economical alternative to standard virgin UHMW that uses a blended version of virgin and recycled UHMW. Reprocessed UHMW is excellent for non-food applications and offers all the benefits of standard UHMW at a much more cost effective price. Reprocessed UHMW features the same low coefficient of friction as standard UHMW while also offering a slightly better wear resistance. Reprocessed UHMW is used extensively for chain guides, wear rails, chute liners, truck liners, hopper liners and many other applications where excellent wear properties are required.

Low Coefficient of Friction

Reprocessed UHMW is used in applications where high levels of friction are likely to arise including conveyor guard rails, augers and wear strips, belt scrapers, chain guides, and idler rollers. Due to an extremely low coefficient of friction, its inherent lubricity minimizes heat-generating friction that tends to gradually destroy steel parts, and ensures smooth, noiseless operation.

Self-Lubricating Formula

High durability, low friction and wear resistance are key reasons why reprocessed UHMW is the material of choice for a myriad of applications. Reprocessed UHMW offers an extremely low coefficient of friction due to a specialized built-in lubricant that replaces unwanted grease and oil. It also enhances efficiency and productivity in many applications. Reprocessed UHMW’s self-lubricating formula helps to extend part life because the internal lubricant ensures that parts will not break or need replacement.

| Item | Specs |

|---|---|

| Size | – 25001250(3-140)mm – 13004300(3-130)mm – 4000*2000(3-130)mm – Can be customized according to customer requirements |

| Color: | – White – Blue – Green – Red – Yellow – Black – Can be customized according to customer requirements |

| Molecular Weight: | – 6 Million – 8 Million – 9.2 Million – Can be customized according to customer requirements |

| Application: | – Buffer strip board; – Train lining board; – Freight car lining board; – Coal car lining board; – Wear-resisting lining board for coal pit; – Wear-resisting lining board for coal washery; – Wear-resisting lining board for coking plant; – Other applicable environment according to customers’ requirements. |