Description

Engineering Plastic Components

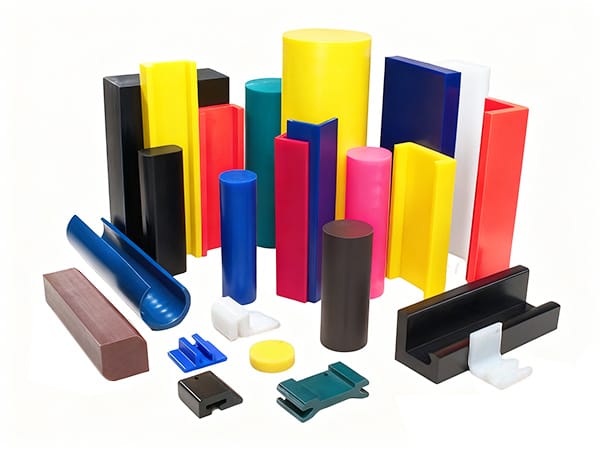

Product Overview

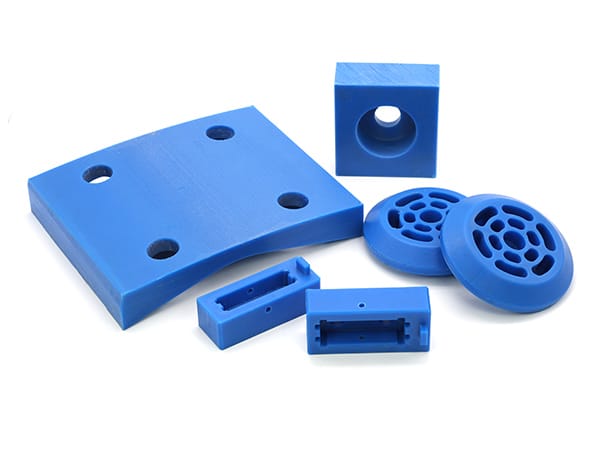

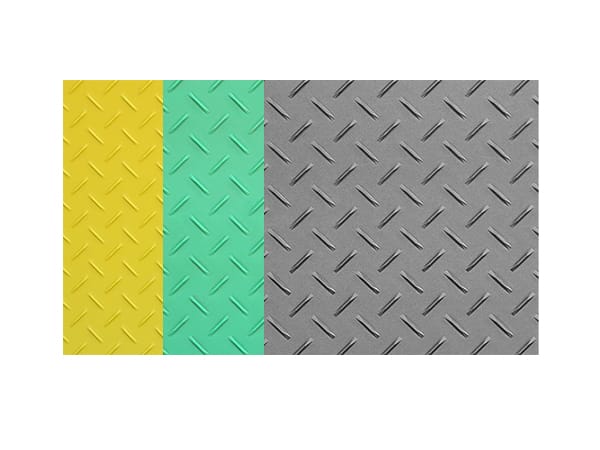

Engineering plastic components are specially designed parts manufactured from high-performance plastics to meet unique industrial requirements. These custom-shaped parts offer a combination of light weight, wear resistance, corrosion resistance, and excellent electrical insulation, making them suitable for a wide range of applications.

Key Features

Lightweight & Durable: Reduces overall product weight while maintaining high strength and longevity.

Wear & Corrosion Resistant: Ideal for harsh industrial environments, including exposure to chemicals and friction.

Good Electrical Insulation: Safe for applications requiring non-conductive materials.

Cost-Effective: Low processing costs combined with high production efficiency make these components economical for large-scale production.

Customizable Geometry: Can be manufactured in complex, non-standard shapes including curved surfaces, asymmetric designs, and integrated features such as grooves or holes.

Applications

Engineering plastic components are widely used across various industries:

Automotive parts

Home appliances

Industrial machinery

Aerospace components

Electronics and electrical equipment

Advantages

Tailored to fit unique assembly needs

Enables complex designs that standard parts cannot achieve

Enhances performance and durability of equipment

Reduces manufacturing costs and improves production efficiency