Table of Contents

Introduction

UHMWPE conveyor wear strips are widely used in modern material handling systems to reduce friction, protect conveyor components, and extend equipment service life. In industries where conveyors operate continuously under heavy loads, material selection plays a critical role in system reliability and maintenance cost control.

This article provides a comprehensive overview of UHMWPE conveyor wear strips, explaining why they are preferred over traditional materials, how they perform in real operating conditions, and how to select the right solution for different conveyor systems.

What Are UHMWPE Conveyor Wear Strips

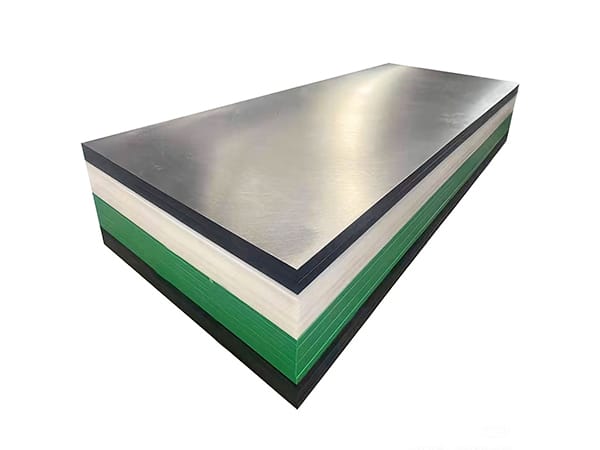

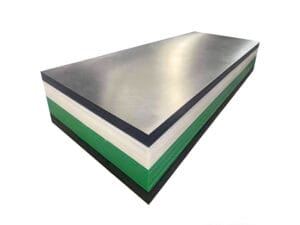

UHMWPE conveyor wear strips are protective components manufactured from Ultra High Molecular Weight Polyethylene. They are typically installed along conveyor frames, guide rails, and sliding surfaces to minimize direct contact between moving chains, belts, or products and metal structures.

Due to their unique molecular structure, UHMWPE conveyor wear strips offer exceptional wear resistance and self-lubricating properties, making them ideal for continuous sliding applications.

Why UHMWPE Is Ideal for Conveyor Systems

UHMWPE conveyor wear strips are specifically designed to handle long-term friction and repetitive motion. The material’s ultra-high molecular weight allows it to absorb mechanical stress without cracking or excessive wear.

Compared with traditional plastics or metal components, UHMWPE conveyor wear strips significantly reduce friction, prevent premature chain wear, and help maintain smooth conveyor operation even under high loads.

Wear Resistance and Service Life Performance

One of the main reasons UHMWPE conveyor wear strips are widely adopted is their outstanding abrasion resistance. In environments involving dust, sand, bulk materials, or packaging debris, UHMWPE maintains surface integrity for extended periods.

Longer service life means fewer replacements, reduced downtime, and lower overall maintenance costs for conveyor systems operating around the clock.

Friction Reduction and Energy Efficiency

UHMWPE conveyor wear strips feature a very low coefficient of friction, allowing conveyor chains and belts to slide smoothly without external lubrication.

Lower friction not only reduces wear but also improves energy efficiency by decreasing drive resistance. This can result in measurable energy savings in large conveyor installations.

Noise Reduction in Conveyor Operations

Noise is a common issue in conveyor systems, especially in high-speed or heavy-load environments. UHMWPE conveyor wear strips help absorb vibration and reduce noise generated by chain movement and product transfer.

This makes UHMWPE wear strips particularly suitable for facilities with strict noise control requirements, such as food processing plants and automated warehouses.

Chemical Resistance and Environmental Stability

UHMWPE conveyor wear strips offer excellent resistance to chemicals, moisture, and corrosion. They do not rust, swell, or degrade when exposed to cleaning agents, oils, or water.

This property allows UHMWPE wear strips to perform reliably in wash-down environments and outdoor conveyor systems.

Temperature Performance in Conveyor Applications

UHMWPE conveyor wear strips maintain stable mechanical properties across a wide temperature range. They retain toughness and impact resistance in low-temperature environments, making them suitable for cold storage and refrigerated conveyor systems.

Temperature stability ensures consistent performance even under changing environmental conditions.

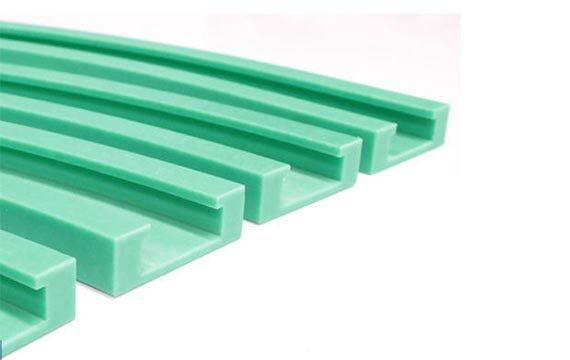

Design Flexibility and Custom Machining

UHMWPE conveyor wear strips can be easily machined into custom shapes and sizes to fit different conveyor designs. CNC machining allows precise slotting, drilling, and profiling based on specific equipment requirements.

Customized UHMWPE wear strips help optimize installation accuracy and improve overall system efficiency.

Typical Industries Using UHMWPE Conveyor Wear Strips

UHMWPE conveyor wear strips are widely used across multiple industries due to their versatility and durability.

Common industries include food and beverage processing, packaging and logistics, mining and bulk material handling, automotive manufacturing, agricultural equipment, and recycling systems.

Comparison of UHMWPE Wear Strips with Other Materials

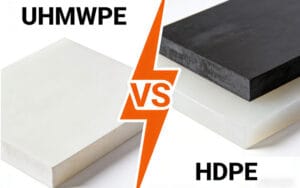

The table below highlights how UHMWPE conveyor wear strips compare with alternative materials commonly used in conveyor systems.

| Material | Wear Resistance | Friction Level | Noise Reduction | Service Life | Maintenance Frequency |

|---|---|---|---|---|---|

| UHMWPE | Excellent | Very Low | Excellent | Long | Low |

| HDPE | Good | Low | Moderate | Medium | Medium |

| Nylon | Moderate | Medium | Low | Medium | Medium |

| Steel | Poor | High | Very Low | Short | High |

This comparison demonstrates why UHMWPE conveyor wear strips are often the preferred choice for demanding conveyor applications.

Installation and Maintenance Considerations

Proper installation of UHMWPE conveyor wear strips ensures optimal performance. Secure fastening, correct alignment, and allowance for thermal expansion are important factors during installation.

Maintenance requirements are minimal, typically limited to periodic inspection and cleaning, which further reduces operational costs.

How to Choose the Right UHMWPE Conveyor Wear Strips

Selecting the right UHMWPE conveyor wear strips depends on conveyor speed, load capacity, operating environment, and product type. Factors such as thickness, color, additives, and surface finish should be considered.

Working with an experienced manufacturer ensures the wear strips are designed to match specific conveyor system requirements.

Conclusion

UHMWPE conveyor wear strips offer an effective solution for reducing wear, friction, noise, and maintenance costs in conveyor systems. Their exceptional durability, chemical resistance, and design flexibility make them suitable for a wide range of industrial applications.

By selecting high-quality UHMWPE conveyor wear strips and proper customization, manufacturers can significantly improve conveyor performance and operational efficiency.

FAQ

What makes UHMWPE conveyor wear strips better than metal components?

UHMWPE wear strips reduce friction, noise, and wear while eliminating corrosion issues associated with metal parts.

Can UHMWPE conveyor wear strips be used in food processing plants?

Yes, food-grade UHMWPE wear strips are commonly used in food and beverage conveyor systems.

How long do UHMWPE conveyor wear strips typically last?

Service life depends on operating conditions, but UHMWPE wear strips usually last significantly longer than HDPE or nylon alternatives.

Do UHMWPE conveyor wear strips require lubrication?

No, UHMWPE has self-lubricating properties and typically does not require external lubrication.

Can UHMWPE conveyor wear strips be custom machined?

Yes, UHMWPE wear strips can be CNC machined to meet specific conveyor design requirements.