Description

The dual color design not only enhances the aesthetic appeal of the UHMWPE conveyor U-trough liners but also serves a functional purpose. By incorporating two distinct colors, operators can quickly and easily identify areas of wear and tear, allowing for timely maintenance and replacement before significant damage occurs. This proactive approach minimizes downtime and extends the overall lifespan of the equipment, ultimately leading to cost savings for businesses. Additionally, the visibility of wear indicators encourages regular inspections, ensuring that conveyor systems operate at peak efficiency. The innovative dual color feature also aids in training new staff, as they can easily recognize the condition of the liners and learn the importance of monitoring equipment health. As industries continue to prioritize efficiency and safety, the demand for such advanced solutions will likely grow. Manufacturers are responding to this trend by developing even more robust and versatile UHMWPE materials that can withstand harsh operating conditions while maintaining their performance characteristics. Overall, the dual color UHMWPE conveyor U-trough liners represent a significant advancement in conveyor technology, combining practicality with visual clarity to enhance operational reliability in various industrial applications.

In the ever-evolving landscape of industrial materials, Ultra-high Molecular Weight Polyethylene (UHMWPE) has emerged as a revolutionary solution for various applications, particularly in the field of conveyor systems. Known for its remarkable durability, low friction properties, and resistance to wear and impact, UHMWPE has become the material of choice for manufacturers seeking to enhance the efficiency and longevity of their equipment. Among its many applications, UHMWPE U-trough liners stand out as a critical component in optimizing conveyor operations. These liners not only protect the conveyor structure from abrasive materials but also ensure smooth material flow, reducing downtime and maintenance costs. In this article, we will delve into the benefits and features of UHMWPE U-trough liners, exploring how they contribute to improved performance and reliability in industrial settings.

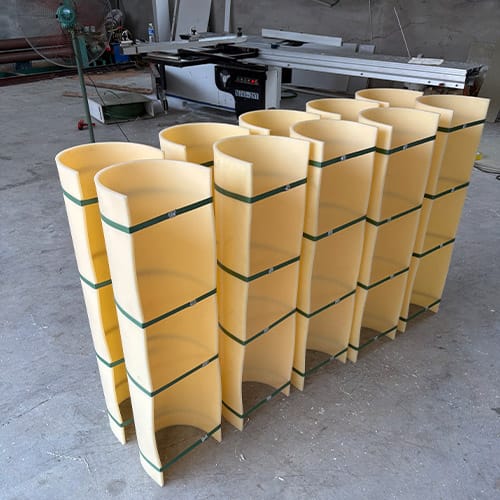

We can produce the UHMW U shape Liner as per customer demands:

Preformed To SizePre-drilled And Beveled ForImmediate InstallationQuieter OperationReduces Wear CostsLightweight For Easy Handling

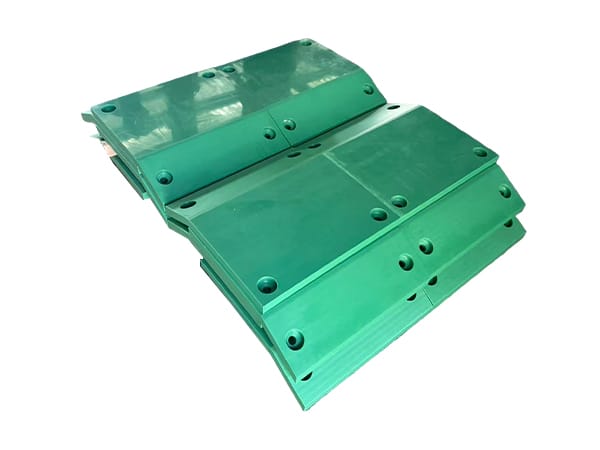

WHERE CAN UHMWPE LINER BE USEDTrailer or tipper liners, silo linings, bucket linings, chute linings, bunker liners, hopper liners, wear plates, machine parts, etc.We can produce any thickness and size UHMWPE sheets as the liner to adhere to virtually any equipment surface to protect that.

CAN UHMWPE LINER BE CUSTOMIZEDGenerally the small thickness liners like 8 mm or 10 mm UHMWPE liners, can be bended with a big arc naturally, under this case, the liner size can be made with large size like 4000 X 2000 mm or 3000 X 1000 mm.But if your equipment is a circle and need to be covered fully with the liner, then need to cut down the UHMWPE sheet into small pieces, to let it perfectly matches the equipment surface.

Shandong Yunzhan Plastic Industry Co., Ltd., can produce the UHMWPE U shape liner as per customer drawing.The two color UHMWPE U shape liner can help customer easily recognize that the replacing of liners in time due to different colors.