Description

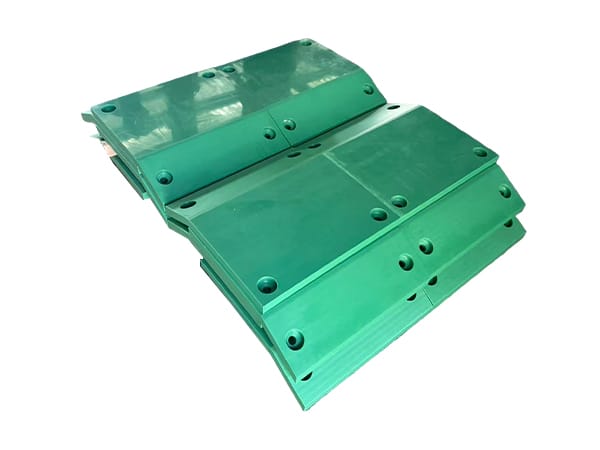

CNC Machining Plastic Gear Nylon Gear

1) Plastic gears material: Nylon; POM; UHMWPE

2) We manufacture plastic parts according to customers’ designs;

3) We can offer material certification,test report and relate surface-treatment report;

4) Platic gears process:CNC machining,Milling,Drilling,Turning;

5) Customized designs are welcome;

Due to its comprehensive properties, its position in engineering plastics has risen rapidly, becoming an important material for mechanical parts, and its usage is increasing

Features:

1. High strength, able to bear the load for a long time;

2. Good resilience, can be bent without deformation, while maintaining toughness, resist repeated impact;

3. Wear-resistant and self-lubricating, it provides better performance than bronze, cast iron, carbon steel and phenolic pressure plate in oil-free or (deoiled) lubrication applications, reducing consumption and saving energy;

4. Noise absorption and shock absorption, MC nylon modulus is much smaller than metal, and vibration attenuation is larger, providing a practical way to prevent noise than metal.

Plastic Gear VS Metal Gear

Plastic is inexpensive, corrosion resistant, quiet operationally and can overcome missing teeth or misalignment. Although plastic is weaker than metal, it has the advantages of self-lubrication, light weight and low noise that metal lacks. Acetal, delrin, nylon, and polycarbonate plastics are common.